| Book Name: | [PDF] CNC G Code and CNC M Code |

| Language: | English |

| Format: | |

| Free Download: | Available |

| E book Particulars : | |

|---|---|

| Language | English |

| Pages | 4 |

| Format | |

| Dimension | 0.267 MB |

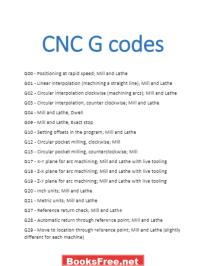

CNC G Code and CNC M Code

G00 – Positioning at fast pace; Mill and Lathe G01 – Linear interpolation (machining a straight line); Mill and Lathe G02 – Round interpolation clockwise (machining arcs); Mill and Lathe G03 – Round interpolation, counter clockwise; Mill and Lathe G04 – Mill and Lathe, Dwell G09 – Mill and Lathe, Actual cease G10 – Setting offsets in this system; Mill and Lathe G12 – Round pocket milling, clockwise; Mill G13 – Round pocket milling, counterclockwise; Mill G17 – X-Y aircraft for arc machining; Mill and Lathe with reside tooling.G18 – Z-X aircraft for arc machining; Mill and Lathe with reside tooling G19 – Z-Y aircraft for arc machining; Mill and Lathe with reside tooling G20 – Inch items; Mill and Lathe G21 – Metric items; Mill and Lathe G27 – Reference return examine; Mill and Lathe G28 – Automated return via reference level; Mill and Lathe G29 – Transfer to location via reference level; Mill and Lathe (barely completely different for every machine) G31 – Skip operate; Mill and Lathe G32 – Thread reducing; Lathe.

G33 – Thread reducing; Mill G40 – Cancel diameter offset; Mill. Cancel device nostril offset; Lathe G41 – Cutter compensation left; Mill. Instrument nostril radius compensation left; Lathe G42 – Cutter compensation proper; Mill. Instrument nostril radius compensation proper; Lathe G43 – Instrument size compensation; Mill G44 – Instrument size compensation cancel; Mill (generally G49) G50 – Set coordinate system and most RPM; Lathe G52 – Native coordinate system setting; Mill and Lathe G53 – Machine coordinate system setting; Mill and Lathe.

G54~G59 – Workpiece coordinate system settings #1 t0 #6; Mill and Lathe G61 – Actual cease examine; Mill and Lathe. G65 – Customized macro name; Mill and Lathe G70 – End cycle; Lathe G71 – Tough turning cycle; Lathe G72 – Tough dealing with cycle; Lathe G73 – Irregular tough turning cycle; Lathe G73 – Chip break drilling cycle; Mill G74 – Left hand tapping; Mill G74 – Face grooving or chip break drilling; Lathe G75 – OD groove pecking; Lathe G76 – High-quality boring cycle; Mill G76 – Threading cycle; Lathe G80 – Cancel cycles; Mill and Lathe.

G81 – Drill cycle; Mill and Lathe G82 – Drill cycle with dwell; Mill G83 – Peck drilling cycle; Mill G84 – Tapping cycle; Mill and Lathe G85 – Bore in, bore out; Mill and Lathe G86 – Bore in, fast out; Mill and Lathe G87 – Again boring cycle; Mill G90 – Absolute programming G91 – Incremental programming G92 – Reposition origin level; Mill G92 – Thread reducing cycle; Lathe G94 – Per minute feed; Mill G95 – Per revolution feed; Mill G96 – Fixed floor pace management; Lathe G97 – Fixed floor pace cancel G98 – Per minute feed; Lathe G99 – Per revolution feed; Lathe M00 – Program cease; Mill and Lathe.

M01 – Optionally available program cease; Lathe and Mill M02 – Program finish; Lathe and Mill M03 – Spindle on clockwise; Lathe and Mill M04 – Spindle on counterclockwise; Lathe and Mill M05 – Spindle off; Lathe and Mill M06 – Instrument change; Mill M08 – Coolant on; Lathe and Mill M09 – Coolant off; Lathe and Mill M10 – Chuck or rotary desk clamp; Lathe and Mill M11 – Chuck or rotary desk clamp off; Lathe and Mill M19 – Orient spindle; Lathe and Mill M30 – Program finish, return to begin; Lathe and Mill M97 – Native sub-routine name; Lathe and Mill M98 – Sub-program name; Lathe and Mill M99 – Finish of sub program; Lathe and Mill

CNC Programming Tutorials Examples G & M Codes: G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist PDF

Author(s): Thanh Tran

Year: 2018

ISBN: B07KFK3R1R

Download CNC G Code and CNC M Code simply in PDF format totally free

![[PDF] Draw Buildings and Cities in 15 Minutes Draw Buildings and Cities in 15 Minutes pdf](https://www.freepdfbook.com/wp-content/uploads/2021/06/Draw-Buildings-and-Cities-in-15-Minutes-218x150.jpg)

![[PDF] Digital Image Processing An Algorithmic Introduction Using Java Digital Image Processing An Algorithmic Introduction Using Java](https://www.freepdfbook.com/wp-content/uploads/2022/06/Digital-Image-Processing-An-Algorithmic-Introduction-Using-Java.jpg)

![[PDF] 43 Years JEE ADVANCED + JEE MAIN Chapterwise & Topicwise Solved Papers 43 Years JEE ADVANCED (1978-2020) + JEE MAIN Chapterwise & Topicwise Solved Papers Physics PDF](https://www.freepdfbook.com/wp-content/uploads/2022/03/43-Years-JEE-ADVANCED-1978-2020.jpg)

![[PDF] Problems in Physical Chemistry for JEE (Main & Advanced) Problems in Physical Chemistry for JEE (Main & Advanced) Free PDF Book Download](https://www.freepdfbook.com/wp-content/uploads/2022/03/Problems-in-Physical-Chemistry-for-JEE-Main-Advanced.jpg)

![[PDF] Engineering Physics (McGraw Hill)](https://www.freepdfbook.com/wp-content/uploads/2021/05/bafc8c2685bb6823a9c56134f7fba5df.jpeg)

![[PDF] Engineering Chemistry By Shashi Chawla](https://www.freepdfbook.com/wp-content/uploads/2022/05/Theory-And-Practicals-of-Engineering-Chemistry-By-Shashi-Chawla-free-pdf-book.jpeg)

![[PDF] Chemistry: An Introduction to Organic, Inorganic & Physical Chemistry Chemistry: An Introduction to Organic, Inorganic & Physical Chemistry](https://www.freepdfbook.com/wp-content/uploads/2022/04/Chemistry-An-Introduction-to-Organic-Inorganic-Physical-Chemistry.jpg)

![[PDF] Essentials of Physical Chemistry Essentials of Physical Chemistry Free PDF Book by Bahl](https://www.freepdfbook.com/wp-content/uploads/2022/04/Essentials-of-Physical-Chemistry-bahl.jpg)

![[PDF] Biological control of plant-parasitic nematodes: soil ecosystem management in sustainable agriculture Biological control of plant-parasitic nematodes: soil ecosystem management in sustainable agriculture](https://www.freepdfbook.com/wp-content/uploads/2022/05/Biological-control-of-plant-parasitic-nematodes-soil-ecosystem-management-in-sustainable-agriculture.jpg)

![[PDF] Human Anatomy: Color Atlas and Textbook Human Anatomy: Color Atlas and Textbook Free PDF Book](https://www.freepdfbook.com/wp-content/uploads/2022/05/Human-Anatomy-Color-Atlas-and-Textbook.jpg)

![[PDF] Concepts of Biology Book [Free Download]](https://www.freepdfbook.com/wp-content/uploads/2022/05/Concepts-of-Biology.jpg)

![[PDF] Essentials of Biology [Free Download] Essentials of Biology Free PDF BOok Download](https://www.freepdfbook.com/wp-content/uploads/2022/05/Essentials-of-Biology-Free-PDF-Book-Downlaod.jpg)

![[PDF] Human Biology Book [Free Download]](https://www.freepdfbook.com/wp-content/uploads/2022/05/PDF-Human-Biology-Book-Free-Download.jpg)